UK magazine MI PRO article on Rotosound strings

A revolutionary exponent of the string manufacturing business, Rotosound founder James How produced strings for some of the biggest names from the world of rock and pop. Here, we take a look back over some of the landmark moments from throughout his career and celebrate his sizeable contribution to the MI industry

From its beginnings as a small, family-run business, Rotosound has gone on to become one of the most renowned brands on the string market. Founded by James How in 1958, and later passed on to his son Jason, the Rotosound approach to string manufacturing has always been based on the same traditional approach to craftsmanship, with both father and son boasting not only a deep understanding of the market, but also an expert degree of engineering acumen. Indeed, both have hand-built virtually every machine that helps produce its range of products from the companys manufacturing facility.

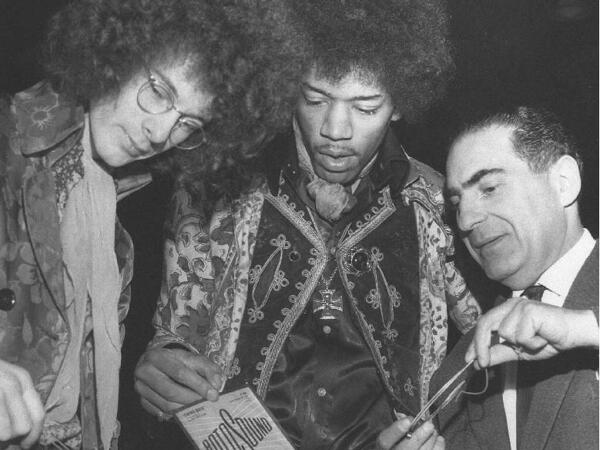

As such, the companys products have been in constant demand from some of the biggest names in rock and pop, with the likes of The Who, Pink Floyd and Jimi Hendrix, to name but a few, among its star-studded line-up of loyal artists.

However, it is for its meticulously designed and crafted products that the Rotosound name is most famed. And with the firm remaining true to its production sensibilities, the high regard with which the brand is held by music professionals the world over looks set to continue for generations to come.

1950s

Rotosound founder James Hows story begins with, of all things, the Zither. Inspired by the Anton Karas-penned soundtrack to the 1952 film The Third Man, which featured the largely unknown instrument, How set about tracking down one of his own. Over the next few years he would develop a talent for the Zither, and amass a substantial collection of the instruments along the way.

An engineer of some repute, he soon decided to combine both his technical and musical prowess to begin manufacturing Zither strings. Before long, he designed his very own winding machine, which required the assistance of two others to turn a handle at each end, which produced a single string.

It didnt take long for How to identify that a new machine could be created that would produce strings in greater quantities for a range of musical instruments.

Following a period of yet further development, operating under the name Orchestral and Jazz Strings, How employed six members staff, including his brother Ronald and sister Joan. Among the firms first clients were The Beatles, Rolling Stones, and the London Symphony Orchestra.

1960s

By the 1960s, How had diversified the business with the production of bass and guitar strings. Almost immediately, the firm began to attract some of the biggest names in rock n roll, working in collaboration with several artists to ensure they received a product to specifically meet their demands. One of the first musicians to work with the brand was The Who bassist, John Entwistle, who helped the firm develop its Swing Bass strings. Other artists affiliated with the brand during this time included Pink Floyd and Jimi Hendrix.

The decade also saw the business change its name to the more memorable Rotosound.

The change in name was shortly followed by the opening of a Denmark Street showroom, with the company expanding into the world of distribution. With the aim of drawing attention to some of the additional products that the firm was now handling, the showroom featured several of its distributed lines, such as Triumph amps and PA systems, Pro Mark drumsicks, and the Rotosound Rhythm Light.

Meanwhile, keen to grow Rotosounds own product range, How created the prototype Rotosound Fuzz pedal.

1970s/80s

The decade in which punk took the UK music scene by storm, Rotosound found favour with several of the genres leading exponents in the 70s, counting The Sex Pistols, The Buzzcocks and The Jam among its many endorsers.

At the same time, Rotosound was also finding an audience across the pond. The company employed the distribution services of New York-based firm Meisel Music, which successfully made Rotosound the top-selling bass string brand in the US. Back in the UK, the companys production facility was running 24/7 in order to meet growing demand.

At the turn of the decade, How developed the RS55 Solo Bass string a pressurewound string engineered to deliver a smooth, optimised feel.

1990s/00s

As the century drew to a close, Rotosound raised the bar once again with the introduction of its Spacer range. The black anodised bass string was bright and roundwound, featuring undercover wraps made from piano wire.

The 90s also saw a new line of guitar strings introduced in the form of the Roto range. Made from nickel, the range has since become the brands most successful line of guitar strings.

In 1994, James How sadly passed away, with his two sons, Martyn and Jason, taking over the company, along with Kathy How (production) and John Doughty (managing director). Towards the end of the 90s, Jason began designing, refurbishing and building a new set of manufacturing machines, which produce around 90 per cent of the firms strings today.

By the mid 00s, the new machines precipitated an increase in production and an increase in exports. As a result, Jason called upon the services of Zach Frederick to run the firms export business.

In 2009, a host of new string lines were introduced. Among these were the black and clear-coated Nexus range and the more traditional British Steels and Pure Nickels.

It goes without saying that constant innovation and improvement remains at the heart of everything bearing the Rotosound name, and it is the combination of business nous, engineering skills and a passion for music that lies at the heart of its success. And with a growing roster of high-profile players continuing to flock to the brand, its prominence in the world of MI shows no sign of slowing.